|

PDA2000

for Laboratory

|

It is characterized to analyze the flocs in the

process of coagulation and flocculation. It is a simple, but

very sensitive monitor for flowing flocs, based on an optical

technique. It is a good tool for determining the optimal dosing

amount of coagulant and forming the good flocs in a laboratory

and pilot scales. |

Application Scopes:

- Selection of optimum flocculant dosage

- Control of dispersion and process

- Assessment of the strength of flocs

- Determining the optimal coagulant dose |

Advantages:

- Easy operating and maintenance

- A very wide range of flocs concentrations can be directly

monitored

- Floc measuring in the real time |

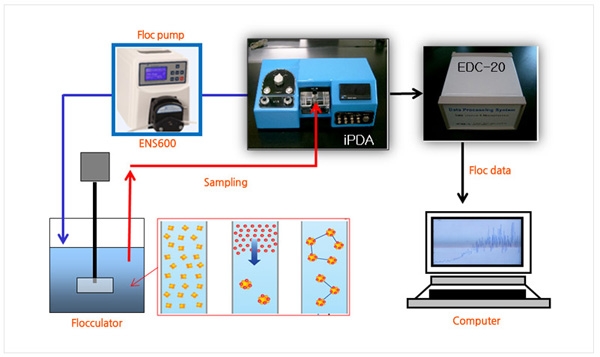

| Set-up for lab test for coagulation

|

|

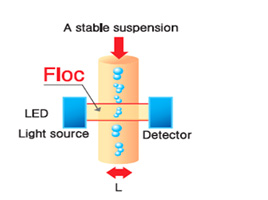

Nature of the Technique

|

The

flowing suspension is illuminated by a narrow beam of light

perpendicular to the direction of flow.

For the PDA2000, a novel flow cell has been developed; transparent

flexible tubing fits in a Perspex block

that houses two precisely aligned fibre-optic probes. The

optical fibres carry the incident and transmitted

light, as shown in Figure 1. The light source is a high intensity

light-emitting diode and the transmitted light is

continuously monitored by a sensitive photodiode.

|

The output from the photodiode is converted to a voltage, which consists

of a large DC component, together with a small, fluctuating (AC) component.

The DC component is simply a measure of the average transmitted light

intensity and is dependent on the turbidity of the suspension. The

AC component

arises from random variations in the number of particles in the sample

(i.e. the volume illuminated by the light beam, typically of the order

of 1mm3 in the

PDA2000). Because the suspension flows through the cell, the actual

sample in the light beam is continually being renewed and local variations

in

particle number concentration give fluctuations in the transmitted

light intensity. These fluctuations cease when the flow is stopped.

The root mean square (RMS) value of the fluctuating (AC) signal

is related to the average number concentration and size of the suspended

particles.

For fairly uniform suspensions, estimates of particle size and number

concentration can be made, but the main use of the PDA2000 is in

the monitoring of

flocculation and dispersion processes.

The RMS value of the fluctuating signal increases, when aggregation

of particles occurs. Measurable changes in the RMS value occur long

before any

visible signs of aggregation are apparent. Conversely, when aggregates

are disrupted, the RMS value decreases, reaching a minimum when

disaggregation

(or dispersion) is complete. The DC value (related to the turbidity)

is much less sensitive to changes in the state of aggregation.

The RMS value of the fluctuating signal increases, when aggregation

of particles occurs. Measurable changes in the RMS value occur long

before any

visible signs of aggregation are apparent. Conversely, when aggregates

are disrupted, the RMS value decreases, reaching a minimum when

disaggregation

(or dispersion) is complete. The DC value (related to the turbidity)

is much less sensitive to changes in the state of aggregation.

Operation of the PDA2000

The flow cell supplied with the PDA2000 can accommodate standard

plastic tubing of either 1mm or 3mm internal diameter. The choice

of tubing depends

on the nature of the suspension and the amount available. The 3mm

tubing requires a minimum suspension flow rate of 20ml/min and would

be used in many

industrial applications. However, for highly turbid suspensions,

the transmitted light intensity might be too low and the 1mm tubing

would then be chosen

because of the shorter optical path length.

Flow rate in the 1mm tube can be as low as 2ml/min, so this might

be chosen for laboratory applications where only small sample volumes

are available.

Because of the high shear caused by flow in narrow tubes, some disruption

of weak aggregates might occur in the 1mm tube at quite low flow

rates.

This effect can be exploited to give an empirical measure of floc

strength. The DC and RMS readings are available as outputs on the

PDA2000.

Both readings can be adjusted by precision 10-turn gain controls,

enabling a wide range of suspension concentrations and conditions

to be monitored.

Another output is the result of dividing the RMS value by the DC

reading. This ratio output is the most useful one for routine monitoring

of flocculation or

dispersion processes. The ratio varies with solids concentration

in a fairly straightforward manner and is almost entirely unaffected

by contamination

of the tube walls in the flow cell or by drift in the electronic

components. These effects cause changes in the DC value (and can

be a serious problem

in flow-through turbidity measurements). However the RMS value of

the voltage fluctuations is changed in the same proportion, so that

the ratio of

the two values does not change. This means that the ratio output

can be monitored for long periods without the need for re-calibration

or re-checking of

the zero reading. Having established the appropriate gain settings

for the suspension under test; the DC, RMS and ratio outputs can

be continuously

monitored on a data logger, chart recorder or other device. Any

one of the outputs can be selected for digital display on the front

panel of the instrument

by push-button switches. Smoothing of the outputs can be selected

by another switch. A limit switch is provided which enables effects

due to air bubbles

or non-representative large particles to be partially compensated.

Response of the PDA2000

Useful readings can be obtained over a very wide range of suspension

concentrations. The limits depend on the nature of the particles

and the tube diameter,

but, as a rough guide, concentrations from a few PPM to several

percent solids can be directly monitored. For more concentrated

suspensions some form

of in-line dilution would be necessary. The limits of particle size

are roughly 0.5 to 100µm, determined largely by the diameter of

the light beam (1mm in the

PDA2000). In non-uniform suspensions, larger particles give the

dominant contribution to the RMS and ratio values. The concentration

and particle

size limits are inter-related to some extent. Thus, for larger particles,

lower concentrations can be detected.

Aggregation of particles can easily cause changes in RMS (or ratio)

output by a factor of five or more before any visible changes in

the suspension become

apparent. Corresponding changes in the DC output are only of the

order of a few percent.

Suggested Applications

|

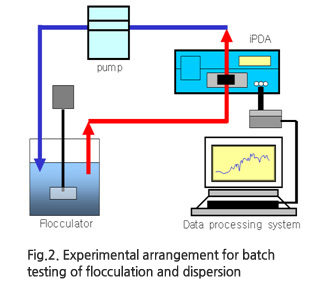

Figure

2

In laboratory studies of flocculation and dispersion processes,

the PDA2000 can be used in several ways.

A very simple approach is to continuously sample from a stirred

vessel as in Figure 2. After passing

through the flow cell the sample can be returned to the vessel

by means of a peristaltic pump or can

go to waste. A range of different dosages of additive (dispersant

or flocculent) can be explored and

the response of the PDA2000 (usually the ratio output) can

be monitored. The speed of response

depends on the suspension concentration - from as little as

a few seconds for concentrated suspensions

to a minute or two for dilute samples. Optimum flocculation

corresponds to a maximum in the ratio reading

after a standard stirring time. For dispersion processes,

the dosage giving the minimum reading is

chosen. As well as giving a rapid indication of the optimum

dosage of a particular additive,

realistic comparisons between different additives can be made

with the simple set-up in Figure 2.

|

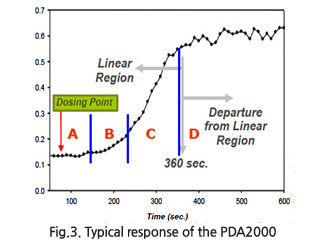

| Figure

3

Figure 3 shows a typical response of the PDA2000 used in this

way. The suspension is of clay (kaolin)

and the additives are a calcium salt and a cationic polymer.

Both of these cause flocculation of the kaolin

particles and the ratio response begins to show an increase

very shortly after addition of the flocculents.

In the case of the polymer the rate of increase is greater,

indicating a more rapid flocculation and

the ultimate value attained is greater than with the calcium

salt, showing that the flocs formed by

the cationic polymer are stronger (they can grow to a larger

size in the stirred vessel).

|

|

The turbidity fluctuation technique as used in the PDA2000,

has been shown to be an effective method of monitoring flocculation

processes in water and

effluent treatment applications. Several other industrial applications

are being evaluated. With an effective, on-line monitor of flocculation

and dispersion

processes, the need for routine measurements of particle change

(or zeta potential) is largely eliminated. |

Ordering Information

|

Order Code |

Description |

| PDA001A |

PDA2000 Particle Dispersion Analyser — 240V

|

| PDA002A |

PDA2000 Particle Dispersion Analyser — 110V |

| PDA108A |

5mm tube adaptor for PDA2000 |

| OXY036Z |

Data Logger Pico ADC-20 (8 channel, 20 bit, USB)

|

| PDA005A |

Converter Box - PDA2000 to ADC-20 |

| PDA300A |

1mm tube |

| PDA301A |

3mm tube |

| PDA302A |

5mm tube |

|